Rouck Bros has been associated with the forest industry

for over eighty years

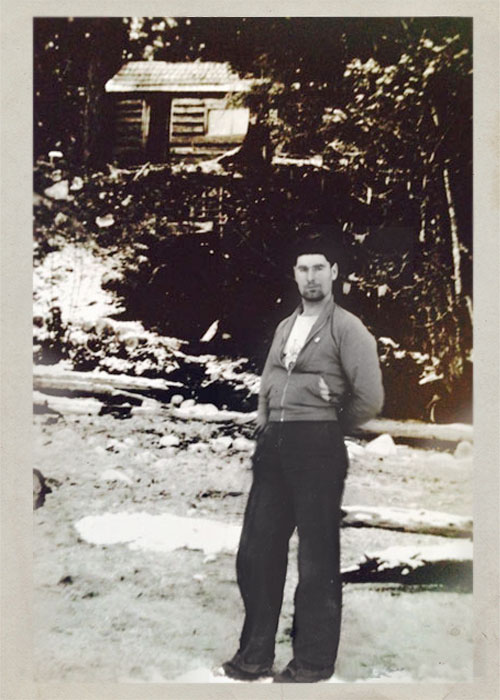

The Rouck Family has been involved in the forest industry since 1942. Back in those days a young Jack Rouck started making poles, axe ties and cord wood with a broad axe and skidding them out with a horse. In 1947 he purchased a small sawmill and produced rough timbers, boards and railroad ties.

Jack Rouck. Moving Cord wood in Winter with the Horses - 1940's

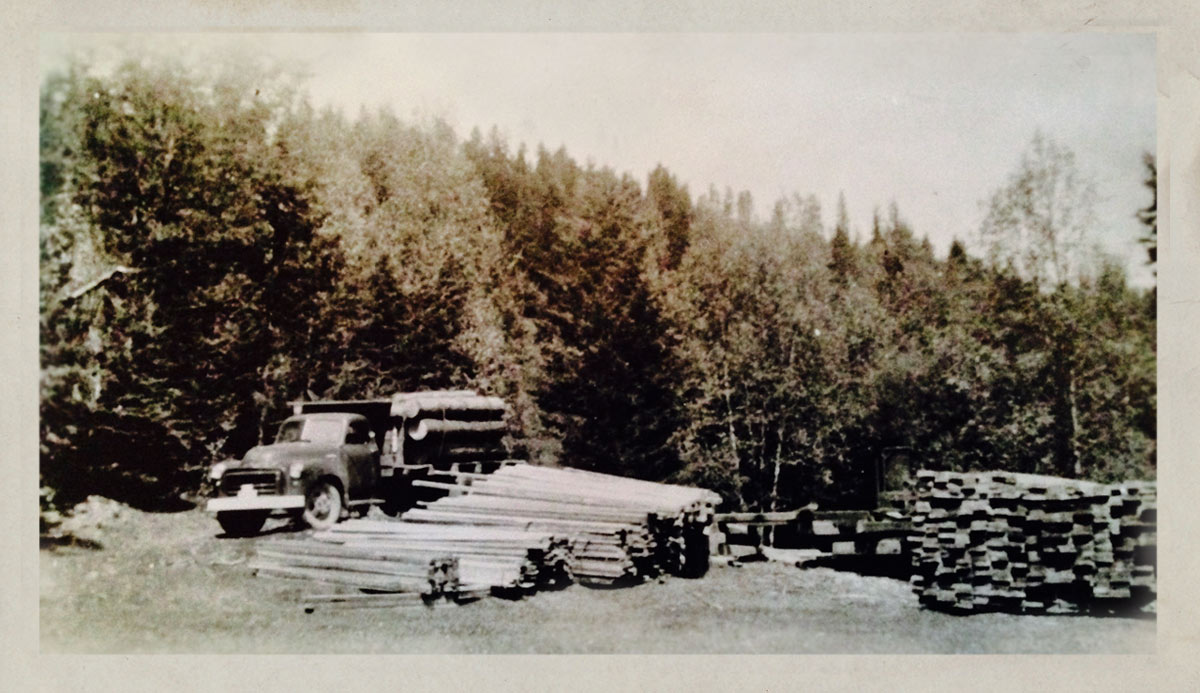

In the 1950’s Jack Rouck started sawmilling. This was done with a portable sawmill which he moved around the area to the wood where he was going to saw. He would mainly saw fir from which he produced such items as railroad ties, dimensional lumber and squares.

Our summer holidays were spent working on the sawmill with Dad. This usually meant piling lumber and doing the cleanup at the end of the day.

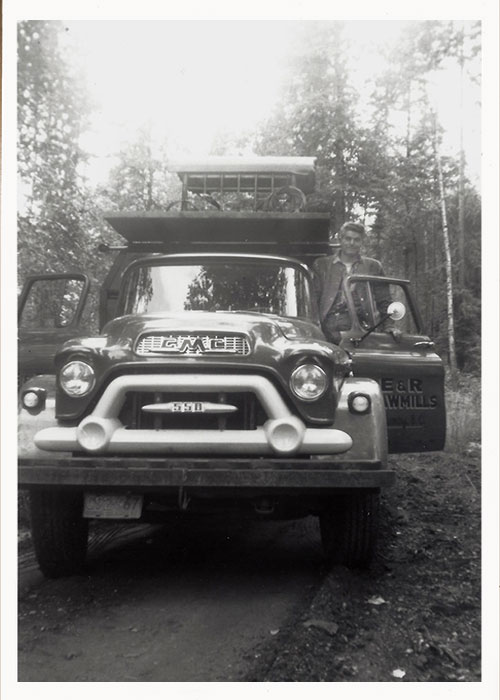

By the 1970’s brothers Earl and Doug Rouck, decided to start off on their own and what better than to herald the lineage and name the company Rouck Bros. Sawmill Ltd.? Dad was thinking of retirement and we felt all the good training and work ethic Dad taught us would be better put to use in our own business rather than working for someone else.

Rouck Bros started off with a small sawmill and quickly learned the other skills needed to run a business, besides piling lumber and wrenching.

Alongside a banker’s advice in financial matters, we could always count on Dad for guidance. He always showed an interest in what we were doing, so much so, that in around 1980 he decided to come out of retirement and come back into the business with us. At this point Rouck Bros bought a bigger mill and had their sight set on more specialty products. In 1980 we started to build the re-manufacture side of our business. This expansion opened up a whole new field for us.

With re-manufacturing and value-added forest products paving the way of the future, we started to develop this side of the business more so than the sawmill end. By the mid 1980’s Dad was ready to retire for good now, but he always continued to be interested in what we were doing and felt confident that we were on the right track.

We started to build lumber sheds to keep the products covered from the changes in the weather. We added a dry kiln. We then purchased a band saw and every year or two we would buy another piece of equipment. Next, a moulder was purchased and that really put the gears in motion for producing value-added products. It always seems that you need another piece of equipment to compliment the ones you have. Subsequently, we purchased a couple of chop saws. As the business grew so did the crew, which increased from the original two employees to a staff of seventeen. Another forklift was purchased and the main re-man building was added. The filing room, used to look after all the saws and cutters, doubled in size. And so it continued to build.

We have added on a wood working shop to our list of expansions. This shop is used for many wood making projects such as building smaller log homes, making live edge mantel pieces, and some rustic wood furniture. We have also taken old wood and recycled it into new products such as flooring and moldings. Old salvaged beams and posts have been cleaned up and brought back to new life with a clean rustic look to them.

Interior Trucker & Logger Magazine - 2005

All this growth in our business was the result of an expanded wood product line. From the beginning when we sawed rough lumber and squares, the idea of doing more with the products was high on our priority list. Now the finished value-added products are endless as the imagination. Our product line includes: cedar siding; paneling and fascia boards; hardwood flooring in fir, hemlock and pine; manufactured log home products, as well as finger joint stock.

Now we kiln dry just about everything we produce as this makes a more stable product when being used in construction. Our log homes and cabin logs are all kiln dried before we run them into their profiles. This makes for less or no shrinkage in the buildings. Our log home and cabin sizes range anywhere from outhouses to large homes and lodges. The homes are produced in either Western Red Cedar, Spruce or Pine.

In the late 1990's Jack Rouck passed on, leaving his legacy to his sons Earl, Doug and grandson, Kevin. Rouck Bros Sawmill maintaines the hard working, friendly ethic of Jack Rouck. As it expands, Rouck Brothers will look forward to an exciting future, including more new markets and new products.